The Growing Need for Automated Material Handling in Today’s Warehouses

The warehouse is a battlefield. The noise of forklifts, the shouts of workers, the endless rows of goods waiting to be moved. It is a place of sweat and toil, where every minute counts and every mistake costs. You know this struggle all too well.

But there is a new way—a smarter way to glide through the chaos and transform it into a cohesive unit.

Automated Material Handling (AMH) combines the precision of a seasoned soldier with the agility of an undefeated champion. Solutions, including autonomous mobile robots (AMRs), robotic arms, conveyor systems, and AI-driven inventory management, come into play. They carry the load. They follow the path. And they never tire. They bring order to the disorder and efficiency to the madness.

AMH is the future, and it is here.

This article will tell you why the need for warehouse automation is peaking, exploring how it reduces labor costs, increases efficiency, and delivers an impressive return on investment (ROI).

What Is Automated Material Handling

Workers hustling. Forklifts darting around. An electrically charged room. Most warehouses share this atmosphere. At least up until that dreadful moment when an error breaks the flow. In an instant, order fulfillment goes into delay and work piles up. Clients get cranky and feel let down by the service.

Automated material handling, or AMH, was designed for this purpose. The system integrates autonomous mobile robots (AMRs), robotic arms, conveyor systems, and AI-driven inventory management into warehouses for seamless, efficient operations.

● AMRs are the agile foot soldiers, navigating your warehouse with precision and transporting goods effortlessly.

● Robotic arms are the tireless workers, lifting and placing items with unmatched accuracy.

● Conveyor systems are the veins of the operation, moving products swiftly and reliably.

● And AI-driven inventory management is the brain, ensuring everything is in its rightful place, optimizing stock levels, and predicting future needs.

No more chaos, no more rework, just smooth, streamlined operations.

There’s a radiant brilliance in the ease, the efficiency, and the sheer innovation of it all.

How AMH Reduces Labor Costs and Increases Efficiency

One of the biggest expenses in material handling is human labor. Hiring, training, managing, and retaining warehouse workers is costly and challenging, especially amid labor shortages and rising wages. Look at the savings opportunities you can attain with automated material handling.

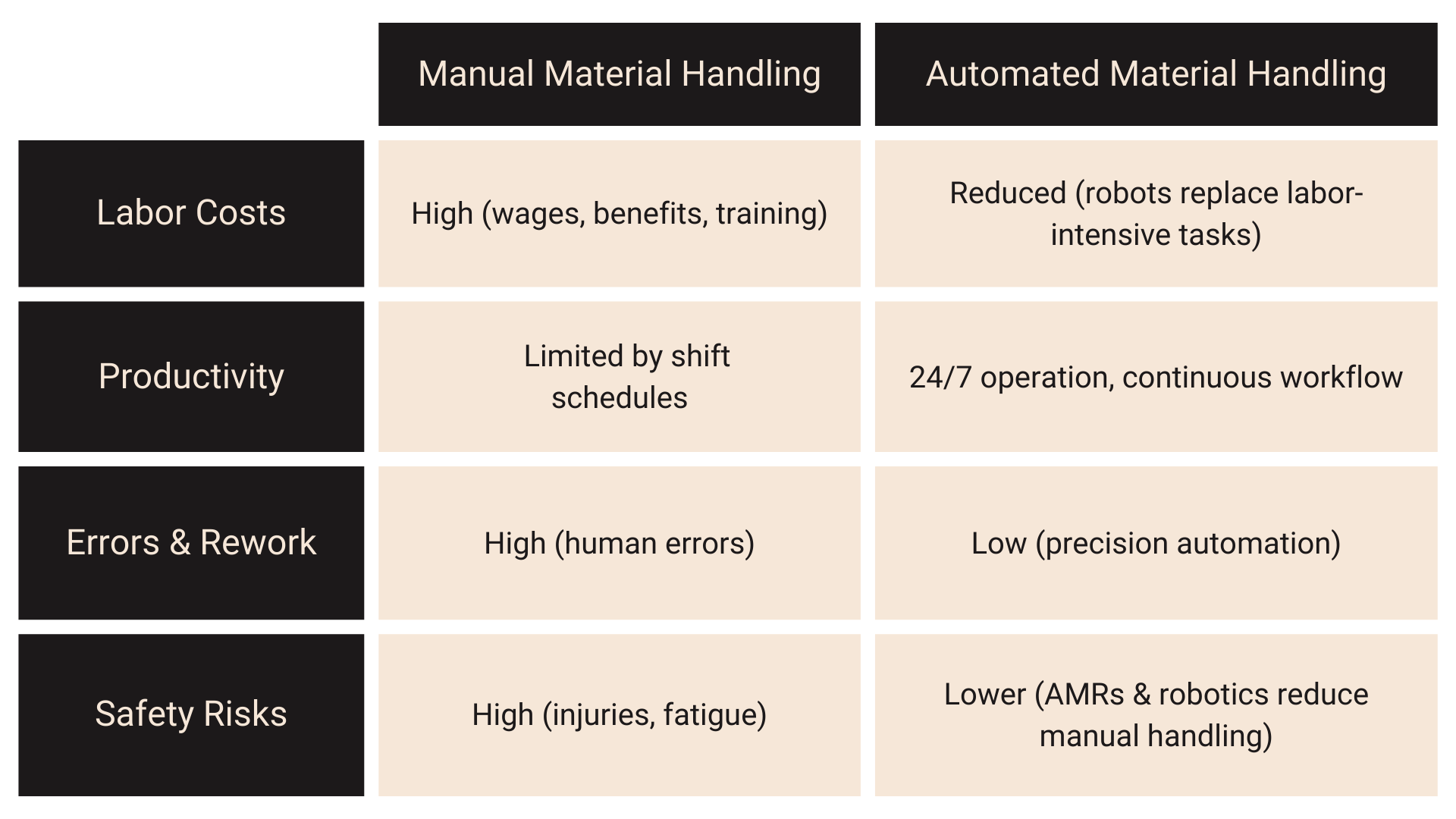

Comparing Manual Labor vs. Automated Material Handling:

Companies that automate material handling can reduce labor costs by 30–50% within the first year of implementation.

And that’s not all.

Beyond labor savings, automation enhances warehouse efficiency by:

● Eliminating delays caused by workforce shortages.

● Optimizing material movement for faster order fulfillment.

● Reducing human error, improving accuracy in inventory and shipments.

● Boosting worker productivity, allowing staff to focus on higher-value tasks

For instance, AMRs and AI-driven robotic picking systems can shorten order cycle times by 30%, ensuring faster deliveries and improved customer satisfaction.

What’s the Return on Investment for AMH?

At first glance, AI, robotics, and other components of the autonomous material handling system might come off as fancy gadgets. But they are not.

Let’s cut the chase and show you the ROI breakdown for AMH technology.

Capital Investment vs. Long-Term Savings

While the upfront cost of implementing AMRs and warehouse robotics can range from $50,000 to $500,000+, the long-term savings outweigh the initial investment.

These key ROI indicators from AMH adoption will spark your attention:

● Reduction in human labor costs ($30,000 - $50,000 per worker per year).

● Decrease in order fulfillment errors (saves thousands in returns & rework).

● Lower warehouse space requirements due to optimized layouts.

● Fewer workplace injury claims (savings on medical costs & legal issues).

ROI Timeline

Before putting money in, you must know when the investment will start paying off and boosting your profits. The ROI timeline for AMH can usually take between 6 and 24 months, as shown below.

Cost Savings in Key Areas of Warehouse Automation for Material Handling

Another virtue of automated material handling lies in the freedom to work with one component at a time. AMRs, robotic arms, AI, and conveyor systems as individual pieces offer unique advantages. Whether you opt for a gradual adoption or a comprehensive implementation, the potential for profit is substantial. Explore the graphic below to appreciate the distinct value each element brings to the table.

Real-Life Scenarios Where AMH Can Turn Warehouse Pain Points into Wins

Transforming pain points into victories is a common goal for every business manager.

With manual material handling, warehouse and logistics operators remain stuck with:

● Lateness in order processing,

● Inventory errors,

● And physical strains.

The alternative, autonomous material handling, introduces a fresh and renewed approach. One where operators can catch a break and actually enjoy work.

The next 3 case studies illustrate how.

AMH also reduces waste, emissions, and energy consumption, with AMRs using up to 80% less energy compared to forklifts & traditional transport methods.

Conclusion: Why Automating Material Handling is Essential for Cost Savings in Modern Warehouses

Warehouses implementing AMRs and robotics for automated material handling typically see a break-even point within 12-24 months due to:

● Lower labor costs

● Increased order fulfillment speeds

● Reduced workplace accidents & insurance costs

The simple but impactful decision leads to:

Processing of higher order volumes without increasing labor,

Achieving industry-leading efficiency & customer satisfaction rates,

And faster operations scalability with lower costs.

Automating your warehouse is the future of the industry. You should get on board NOW!

What should be your next step?

Choose Verdusco Automation as your AMH solutions partner.

At Verdusco Automation, we specialize in:

● Custom AMR solutions tailored to your warehouse needs.

● Scalable automation solutions to future-proof your operations.

● Industry expertise in warehouse efficiency & cost reduction.

Ready to cut costs and boost efficiency with automation?

Contact Verdusco Automation today!

📩 Get in touch now:https://www.verduscoautomation.com/contact.